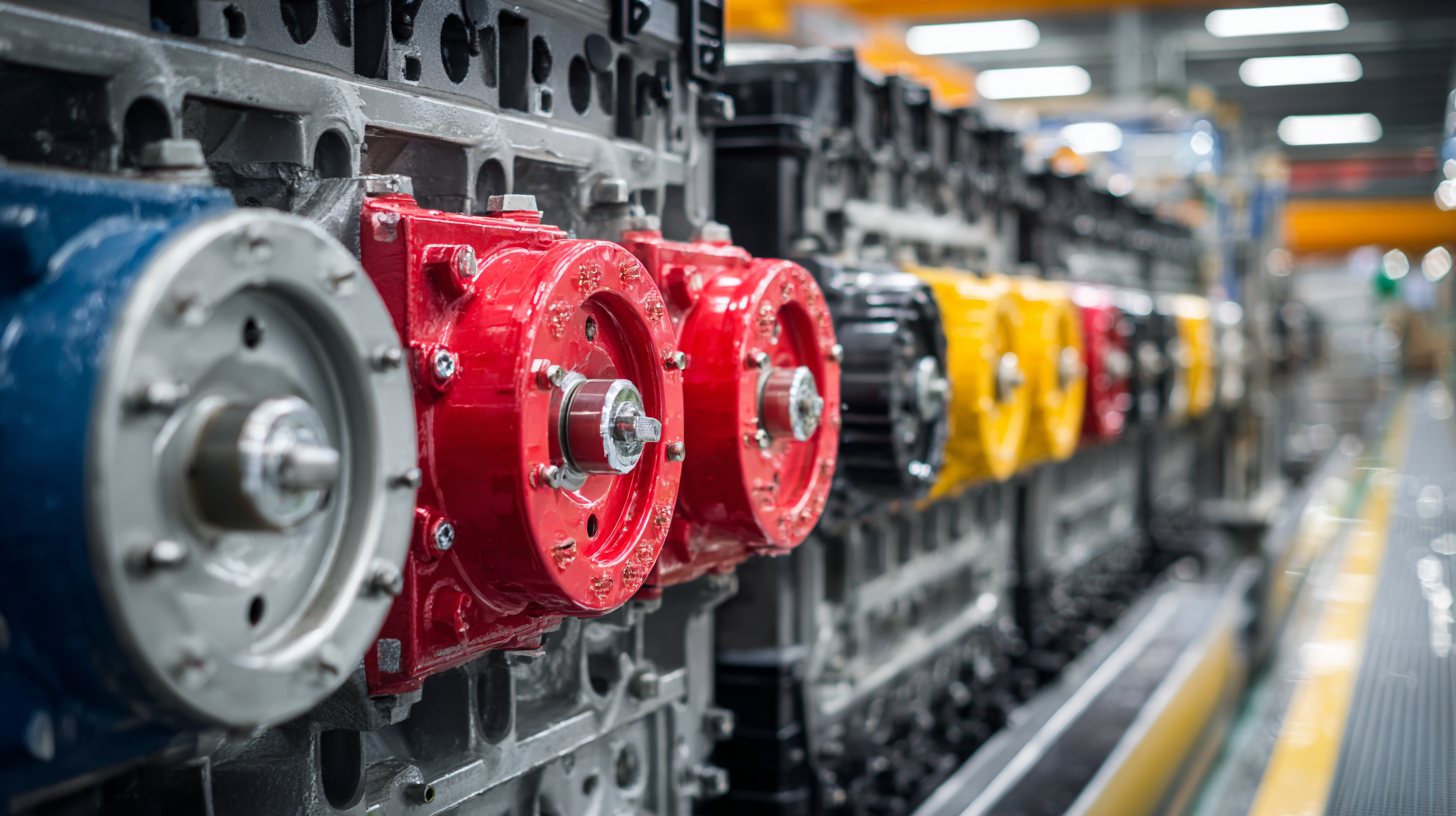

The quest for effective solutions in the realm of hydraulic and pneumatic systems has illuminated the pressing need for innovative alternatives to traditional mechanisms, particularly the Bypassing Cylinder. Recent industry reports indicate that the global market for hydraulic cylinders is projected to reach $15.76 billion by 2025, revealing a burgeoning demand for alternatives that can enhance efficiency and reduce operational costs. However, conventional Bypassing Cylinders often present challenges such as maintenance complexities and limited adaptability in various applications.

As manufacturers and global buyers explore viable alternatives, it's crucial to uncover creative designs and technological advancements that not only address these issues but also provide superior performance. This blog will delve into the emerging alternatives to Bypassing Cylinders, highlighting their benefits, potential applications, and the impact they may have on the future of industrial fluid power systems.

In the ever-evolving landscape of global supply chains, the quest for efficient alternatives to traditional components, such as bypassing cylinders, has become crucial for businesses looking to maintain competitive advantages. As the demand for innovative solutions grows, companies are exploring various replacements that not only enhance operational efficiency but also align with sustainability goals. This exploration isn't just a matter of cost; it's about ensuring a resilient supply network capable of withstanding disruptions.

Furthermore, recent developments in the oil and gas sector have underscored the importance of reliability in supply sources. With regulatory bodies emphasizing the need for adequate stockpiles, businesses are compelled to rethink their inventory strategies. This situation encourages the exploration of alternative bypassing cylinders that can provide the same level of performance while ensuring compliance and stability in logistics. As organizations face the dual challenge of optimizing operations and responding to regulatory demands, the shift towards innovative alternatives becomes more than an option—it is a necessity for thriving in a complex global market.

Emerging technologies are significantly reshaping the dynamics of the bypassing cylinder market, driving innovation and offering new solutions to global buyers. One notable trend is the increased incorporation of smart materials, which provide enhanced durability and performance. According to a recent report by MarketsandMarkets, the global bypassing cylinder market is projected to reach $4.2 billion by 2027, growing at a CAGR of 6.5%. This growth is attributed to the increasing demand for energy-efficient and sustainable manufacturing processes.

As companies seek to streamline their operations, the adoption of IoT-enabled bypassing cylinders offers real-time monitoring and predictive maintenance capabilities. This shift not only improves operational efficiency but also significantly reduces downtime. For buyers looking to navigate this evolving landscape, it is crucial to stay informed about the latest technological advancements.

**Tip:** Regularly attend industry conferences and participate in webinars to glean insights into emerging technologies and best practices in the bypassing cylinder market. Engaging with industry experts can provide valuable information that helps in making informed purchasing decisions.

Furthermore, leveraging data analytics can help buyers make more strategic choices by identifying trends and optimizing their supply chains. Embracing these innovations will not only keep businesses competitive but also contribute to a more sustainable future in manufacturing.

| Innovation Type | Technology Used | Market Potential ($ Billion) | Regional Focus | Key Benefit |

|---|---|---|---|---|

| Smart Bypassing Cylinder | IoT Integration | 1.5 | North America | Enhanced security |

| Eco-Friendly Cylinder | Biodegradable Materials | 1.2 | Europe | Sustainability |

| Self-Locking Cylinder | Mechanical Innovation | 0.8 | Asia-Pacific | User convenience |

| Digital Bypassing Cylinder | Fingerprint Recognition | 2.0 | Global | High security |

| Remote Access Cylinder | Mobile Connectivity | 1.6 | North America | Convenience |

In recent years, the global bypassing cylinder market has witnessed significant transformations driven by dynamic market trends. According to a report by Market Research Future, the market is projected to grow at a CAGR of 4% from 2023 to 2028, driven primarily by the increasing demand for efficient hydraulic solutions in various industries such as manufacturing and construction. Innovations in materials and design are pivotal in enhancing performance and reducing operational costs, leading to heightened interest among global buyers seeking advanced bypassing cylinder options.

Moreover, sustainability considerations are increasingly shaping product development in the bypassing cylinder sector. A survey conducted by Global Industry Analysts reveals that approximately 60% of industry leaders are now prioritizing eco-friendly materials and manufacturing processes. This trend responds to the growing regulatory pressures and consumer demand for greener alternatives, positioning companies that innovate with sustainable solutions advantageously in the market. By integrating cutting-edge technologies like IoT and AI, manufacturers are not only improving product functionality but also enabling predictive maintenance, thus offering substantial long-term cost savings to end-users.

Moreover, sustainability considerations are increasingly shaping product development in the bypassing cylinder sector. A survey conducted by Global Industry Analysts reveals that approximately 60% of industry leaders are now prioritizing eco-friendly materials and manufacturing processes. This trend responds to the growing regulatory pressures and consumer demand for greener alternatives, positioning companies that innovate with sustainable solutions advantageously in the market. By integrating cutting-edge technologies like IoT and AI, manufacturers are not only improving product functionality but also enabling predictive maintenance, thus offering substantial long-term cost savings to end-users.

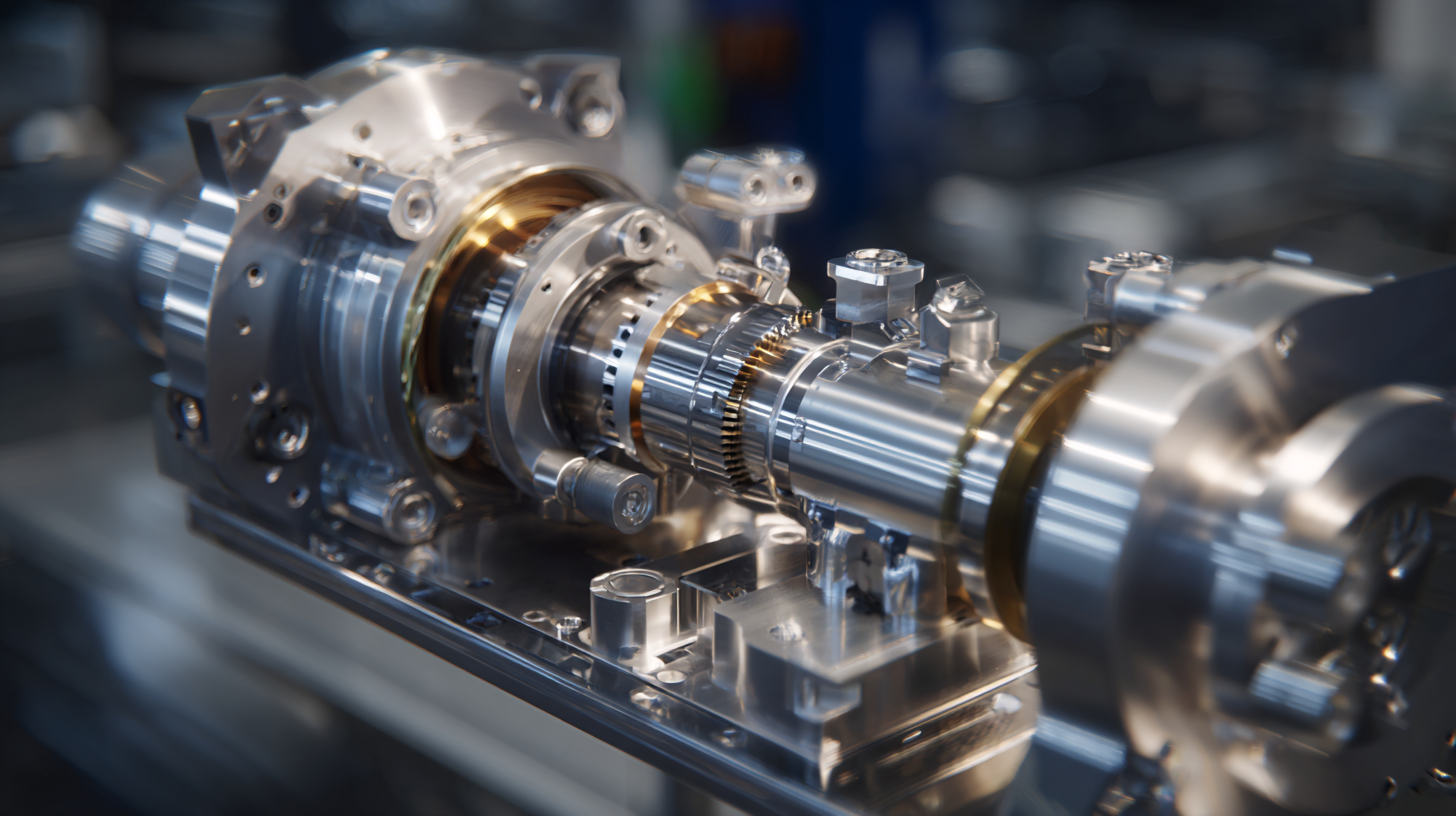

In the quest for cost-effective solutions, the comparative analysis of bypassing cylinders has garnered significant attention among global buyers. Recent studies underscore the importance of optimizing energy efficiency in hydraulic systems, particularly through innovative approaches like neural network model predictive control (NN-MPC), which significantly enhances position control and reduces power consumption. For instance, implementing advanced control strategies has the potential to cut energy usage by up to 30%, making these systems not only more efficient but also more appealing to buyers looking to reduce operational costs.

Moreover, as the demand for sustainable technologies grows, examining the lifecycle impacts of different bypassing cylinder solutions becomes crucial. A comprehensive survey of energy storage technologies reveals that effective scheduling and sustainability practices can lead to a 25% reduction in emissions associated with energy production. This aligns perfectly with the goals of businesses aiming to integrate renewable energy solutions while maintaining budgetary constraints. By focusing on these innovative alternatives, global buyers can leverage new findings to make informed decisions that balance cost, performance, and environmental impact.

The quest for sustainable practices in cylinder production is gaining momentum, as manufacturers explore eco-friendly alternatives to conventional materials. As the push for greener solutions intensifies, research indicates that bio-based production methods can significantly reduce the environmental impact associated with traditional cylinder manufacturing. According to a recent study, co-producing green hydrogen and bio-acids from biomass not only offers a pathway to cleaner energy but also enhances economic viability. This dual production process demonstrates the feasibility of transitioning toward sustainable practices while also meeting energy demands.

Moreover, the microbial production of natural pigments, such as indigoidine derived from soybean okara, exemplifies innovation in sustainable dye production. The rising trend toward eco-friendly dyes in textiles highlights the potential for utilizing waste materials, thus closing the loop in production cycles. By harnessing these novel approaches, companies can not only abide by sustainability goals but also cater to a growing consumer preference for environmentally responsible products. Industry reports suggest that adopting such eco-conscious practices could lead to a 30% reduction in carbon footprint across the manufacturing processes.

This bar chart illustrates the sustainability impact scores of various innovative alternatives in the production of bypassing cylinders. Higher scores indicate stronger contributions to sustainability efforts within the industry.